Cancer survivor’s hope through innovation.

Nicola Salmond’s first thought was that the small ulcer inside her mouth was caused by her wisdom teeth. Her wisdom teeth were removed. The ulcer stayed. Then, a biopsy revealed that the ulcer was, in fact, a squamous cell carcinoma. Cancer. Specifically, a mouth cancer that is aggressive and can be life threatening.

“People think they’re invincible, right?” says Salmond, a warm and straight-talking person, obviously still disquieted by the memory of the diagnosis. “I’ve never been fitter than I am now in my 40s. Yet there was this thing in my mouth. No symptoms at first, just this thing.”

Determined to stay in the lives of her three young daughters, Salmond joined in the search for a surgeon with the skills to help her. Professor Jonathan Clark (MBiostat ’12) came up early as one of the best in the field of head and neck surgery. Appointed a Member of the Order of Australia in 2019, Professor Clark is one of a team of highly regarded surgeons at Chris O’Brien Lifehouse in Camperdown, which performs the highest volume of complex head and neck cancer surgery in Australia. Highly skilled in removing tumours affecting the mouth, throat, face, salivary glands and thyroid, he also had parallel skills in facial reconstruction.

This would prove vital when it was found that removing Salmond’s cancer would mean taking out part of her jaw that held five teeth. Across the world, this is considered highly specialised and complex surgery. In fact, when SAM spoke to Professor Clark online at around 8pm, he was in his office, looking tired, having come straight from an operation.

“A quick operation might take six hours. But the slow ones can go for up to 18 hours. This one was slow,” he says. An affable though reserved speaker, Professor Clark admits to being less than extroverted; his favourite pastime is fishing. “Head and neck surgery is complex, but that’s one of the things that attracted me to it. It’s like working on a highway that crams in everything that goes from your brain to the rest of your body.”

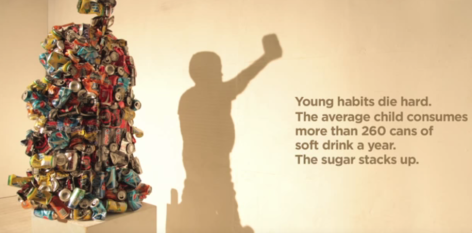

In recent years there has been a rise in mouth cancer, particularly among young Australian women with none of the usual risk factors, like Salmond. With the causes of this as yet unknown, Professor Clark is seeing a new group of patients needing specialised treatment.

Historically, the surgical techniques that were used could leave people terribly disfigured, with difficulty eating, drinking, even breathing. Social isolation, unemployment and depression were common outcomes. The reality for surgeons in the past though was that a lot of what they did was highly informed guesswork.

Salmond was fortunate in the sense that her cancer occurred at a time when the treatment of head and neck cancers has made significant, technology-driven advances, like digital surgical planning.

In the same way that a modern building is tested using an engineering simulation before it is built, digital planning uses CT scans to create a ‘digital twin’ of the patient to which various surgical approaches can be applied, with an algorithm predicting outcomes – good and bad. This allows surgeons the incredible luxury of a pre-operation rehearsal.

The technology is transformative and continues to evolve. Currently, the surgeon instructs a design engineer who inputs information into a workstation. A virtual reality-based version of this idea is being developed where the surgeon has direct input and manipulates the information themselves in real time.

Professor Clark is helping drive these advances through his role as the first Lang Walker Family Foundation Chair in Head and Neck Cancer Reconstructive Surgery at the University of Sydney, in collaboration with Chris O’Brien Lifehouse. The foundation – created by noted property developer Lang Walker – gave $3.9 million to create the Chair and help bring new technologies to the fore in Professor Clark’s field.

“I spoke to Lang about our research and the vision we have for it,” says Professor Clark. “I think it was our move into the technology side of things that really captured his interest. He’s a builder, after all, so he loves the idea of making things that help patients.”

One of the drivers of the ‘making’ is 3D printing. Previously, if a patient needed a bespoke prosthetic, it would have been ordered from overseas at great expense. Allowing that many of Professor Clark’s patients don’t have huge financial resources to draw on – and that dental work is generally not covered by public health funding – cost is a significant issue.

3D printing lets us look at new ideas and investigate them quickly, right here. It’s made us very nimble. I work with an amazing team that were able to prototype the jaw stretcher and focus on refining it for our patients’ needs.

“People have had to mortgage their houses,” says Professor Clark, who is dedicated to advancing ideals of equity in his work. “If you have breast cancer, your reconstruction or prosthesis is covered. With mouth cancers, there is no dental cover.”

An example is the jaw stretcher. It sounds torturous, but after jaw surgery and radiology, it is common for scar tissue to build up and cause the patient’s jaw to lock. The stretcher is used to keep the jaw flexible, but it is currently prohibitively expensive and slow to arrive in Australia – typically taking around six weeks.

Thanks to 3D printing, Professor Clark and his team are now prototyping their own jaw-stretching device. You can sense real excitement in Clark, as he talks about the improved future this promises.

“3D printing lets us look at new ideas and investigate them quickly, right here,” he says. “It’s made us very nimble. I work with an amazing team that were able to prototype the jaw stretcher and focus on refining it for our patients’ needs.

“It’s been amazing. Hundreds of patients use this device already, and we think it has huge potential impact.”

Many of these cutting-edge biomedical innovations are the result of a new multidisciplinary research partnership between the Faculty of Medicine and Health and the Faculty of Engineering – specifically, the School of Aerospace, Mechanical and Mechatronic Engineering. This is where PhD student, Ben Ferguson, and ARC Future Fellow Professor Qing Li, are designing the next generation of reconstruction devices – specifically 3D-printed scaffold-based implants.

While Clark shaped a piece of bone from Salmond’s hip to replace her damaged area of jawbone, University engineers like Ferguson and Professor Li are exploring how 3D printing can provide an implant that is perfectly tailored to that patient’s body.

“The 3D printing will create precise bone implants made of ceramic or polymer,” says Ferguson. “They will facilitate the regeneration of the surrounding tissue, then eventually the scaffold will dissolve away, leaving brand new, living tissue in its place.”

Now a couple of years on from her operation, Salmond is amazed that Clark was able to do such a dramatic piece of surgery on her face, and that his work is now almost invisible.

“All I remember is being really emotional after it,” she says. “The thing is, you’ve been strong for so long, and for your kids. And then you wake up and find [the cancer] is gone – well, there’s just this overwhelming sense of release.”

Written by George Dodd for Sydney Alumni Magazine. Photography by Stefanie Zingsheim